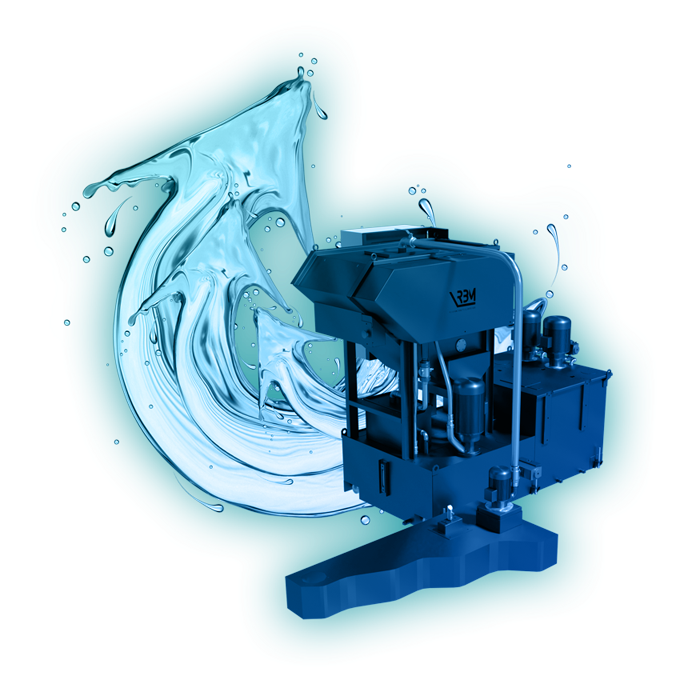

Solutions for the management of

chips and coolant in machine tools

Metal and non-metal chip management

Versatility of solutions

Higher levels of coolant and tanks cleaning

Innovative pressure/flow rate relationship’s management

Automatic recognition of the tool in use

Reduction of the production cycle period

Optimization of energy consumption and reduced environmental impact

Dynamic tramp oil separation of coolant

Products

News

-

22Dec

Summer Holidays 2023

RBM International will be closed for the summer holidays from August 05th to 27th 2023.

-

07Oct

Open House Overmach 15-19 October 2019

We will be present at the Open House Overmach from 15th to 19th October 2019 in Parma with the CO-RE solution, which can be matched to any machine tool and suitable for processing any material and type of chip.

-

01Jun

RA-IN Independent automatic coolant top-up

The development of RA-IN comes from a careful analysis of the needs of production, which highlighted the need to restore the correct level of coolant in the machine tool tanks: this is considered of strategic importance to be able to work H24 or in any case over several shifts unmanned.